Experiment

The experimental setup used in our

experiments to synthesize carbon nanotubes consist of an electric

furnace with an effective heating length of 200 mm, a quartz reactor of

18 mm inner diameter and a nozzle with two concentric tubes of 0.8 and

1.8 mm inner diameter, respectively. The inner tube of the nozzle

carries the metallocene–hydrocarbon solution, while the outer one

guides the carrier gas in order to pulverize the solution.

We investigated the effect of the

experimental parameters (temperature, catalyst concentration, flow rate

of carbon source and carrier gas), the influence of metallocenes

(ferrocene, cobaltocene and nickelocene) and hydrocarbons (benzene,

toluene, xylene, cyclohexane, cyclohexanone, n-hexane, n-heptane,

n-octane and n-pentane) on the quality and quantity of the nanotubes

grown by spray-pyrolysis. The product deposited on the walls of the

quartz tube was collected and analyzed by transmission and scanning

electron microscopy (TEM and SEM), X-ray diffraction, and scanning

tunneling microscopy (STM).

Results

MWCNTs were produced with maximum yield when ferrocene–nickelocene

catalyst mixture was used and xylene was found to be the most efficient

carbon source. For xylene the weight of purified carbon nanotubes

normalized to the weight of catalyst material is higher than 50%. Good

quality thin MWCNTs were produced from n-octane, but in lower quantity

than in case of xylene. Nevertheless, the production of MWCNTs was

possible in case of all mentioned hydrocarbons and metallocenes. For

xylene the best results were obtained at 800 ºC, 1.5 g ferrocene

in 50 ml xylene catalyst concentration, 500 l/h carrier gas flow rate

and 1 ml/min carbon source flow rate.

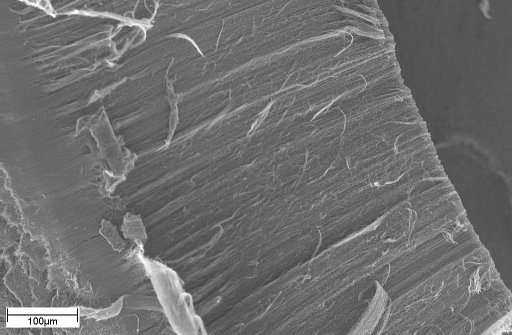

SEM image of the carbon nanotubes

|

|

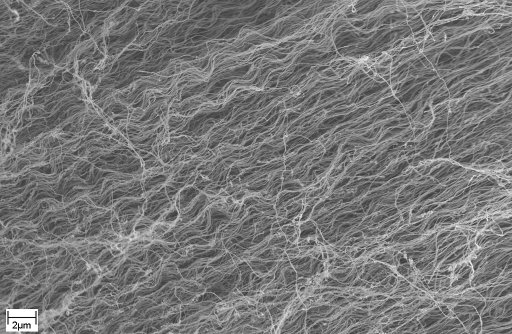

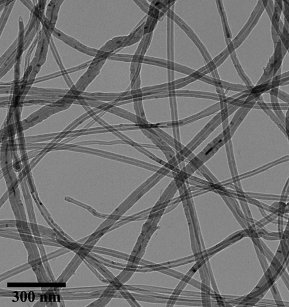

| TEM

images of the samples produced of xylene and octane, respectively |

|

|

|

| Diameter

distribution of the nanotubes produced of xylene |

Comparison

of the outer and inner diameters of the carbon nanotubes produced of

different carbon sources. The diagram shows the diameter intervals

containing 80% of the nanotube diameters measured in the sample. |

Publications

Tapasztó L., Kertész K., Vértesy Z.,

Horváth Z. E., Koós A. A., Osváth Z.,

Sárközi Zs., Darabont Al.,. Biró L. P:Diameter and morphology dependence on experimental conditions of carbon nanotube arrays grown by spray pyrolysis

Carbon 43 (2005) 970–977.